Build Your Own Robot

Learn how to build a robot like those featured at the 2018 USA Science and Engineering Festival's 'Robot Rescue' booth

Thank you for visiting our booth during the 2018 USA Science and Engineering Festival.

Our team put together comprehensive instructions on how you can build the same robot you controlled at the show.

Disclaimer

Please note that while we have designed this as a robot that kids can use to experiment with, assembling the robot does require the use of power tools, soldering irons and other potentially dangerous tools. Adult supervision or intervention is HIGHLY recommended. Lockheed Martin provides these instructions for educational purposes only and takes no responsibility for any injuries or damages suffered.

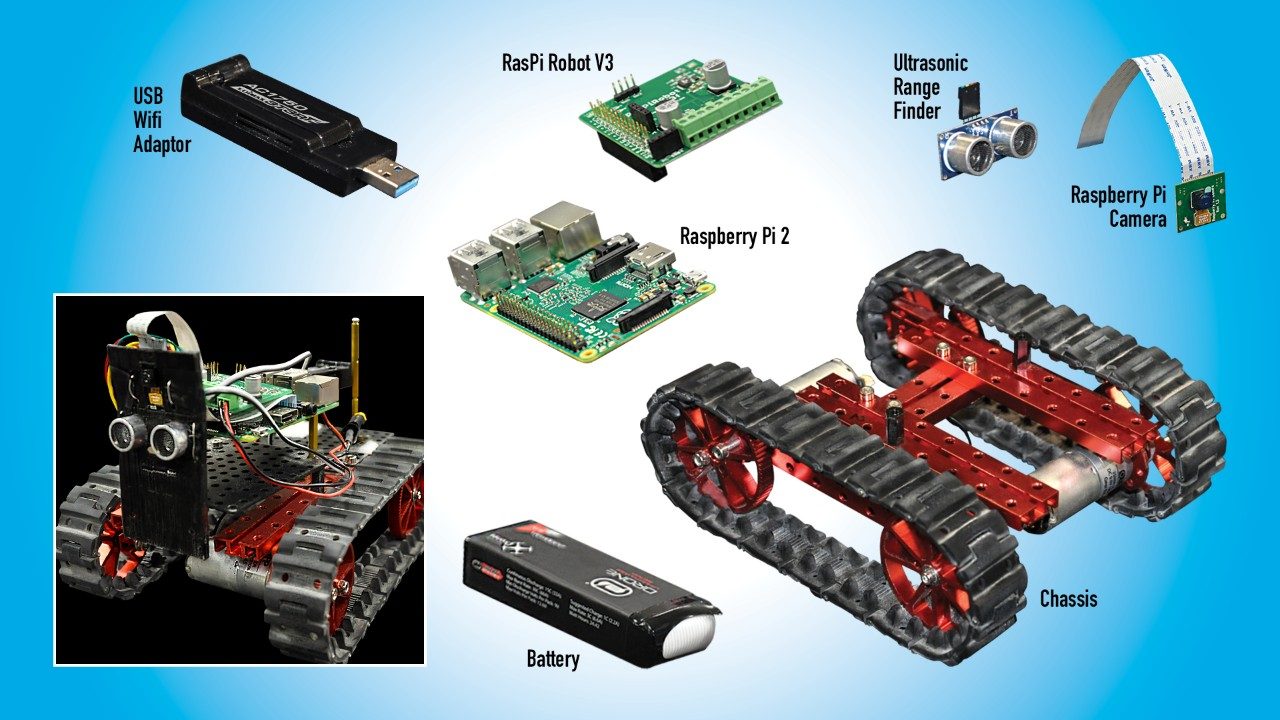

Parts List

Note, these are where we purchased the parts, but they may be found elsewhere. The links are not meant to be an endorsement of the suppliers. The robot chassis we used for the activity has been discontinued, so the chassis listed below are similar, but not exactly the same, as the ones used at the USA Science and Engineering Festival.

Robot Chassis |

|

Raspberry Pi 2 |

https://www.adafruit.com/products/2358 or |

RasPi Robot v3 |

https://www.adafruit.com/products/1940

|

Raspberry Pi Camera |

https://www.adafruit.com/product/3099

|

Standoffs |

|

USB Wifi Adaptor |

|

Battery Pack |

or (Advanced users)

http://www.horizonhobby.com/xt-60-connector-set--35mm-%282%29-dync0140 and

Note that the advanced option will run much longer on a single recharge but is recommended only for people with prior RC model car LiPo battery experience, and requires a LiPo battery charger unit, not listed. |

Micro SD Memory Card |

Get something that is microSD, class 10, and 8GB (or larger) in size. |

Other Tools and Materials Needed

Sticky back Velcro®

Electrical tape

Long metal twist ties (like from loafs of bread)

22-24 gauge braided wire (can use solid core, but braided is easier to work with as it’s more flexible)

Soldering iron

Wire stripper

Small screwdrivers (both flat + Phillips head)

Small adjustable wrench

Drill with bits

Pen/marker with fine tip

Assembly Instructions

- Follow the provided instructions for the tank up to and including step 13 https://www.osepp.com/downloads/pdf/Tank_instructionbooklet.pdf

- Attach the corners of the long end of part BP11X9 (black holed board) to the standoffs on the cassis. Orient so the board is facing forward. Front of board should be aligned with front of chassis. Screw in uses hex nuts (HEXM4X8).

- Attach the second black holed board to the back of the chassis using the hex nuts. This will provide a surface for the battery.

- Assemble the tank treads (step 21). Be careful because the treads rip easily. Install the treads onto the chassis (Step 22).

- Use (2) 25mm Male standoffs to attach the Raspberry Pi to the black board. NOTE: Make sure the screw heads are not making contact with any electrical components on the Raspberry Pi board!

- Wrap electrical tape around the back of both the Raspberry Pi camera board, as well as the ultrasonic range finder unit such that there are no electronic pieces exposed.

- Push the ultrasonic range finder through the holes in the 3D printed bracket such that the connection pins are facing upwards.

- Take 2 twist ties and strip any coating off them so that only the bare metal wire remains. Slide one through each pair of holes in the front of the sensor bracket and through the holes in the ultrasonic sensor such that the ends of the twist ties are sticking through the back of the sensor. Twist the wires so they form a snug fit against the electrical tape on the back of the sensor. Do NOT let the wires directly touch any electrical components! Repeat this on the other side. This should hold the ultrasonic detector in place on the bracket.

- Position the Raspberry Pi camera through the top opening in the bracket with the ribbon cable coming out of the top.

- Similar to step 7, do the same for the Raspberry Pi camera to hold the camera to the sensor bracket.

- Position the sensor bracket onto the front of the robot. Use spare hex nut from chassis kit to attach sensor bracket to the black board.

- Gently lift the little latch on the Raspberry Pi computer that sits between the audio jack and the HDMI port. It will only move up slightly. Once unlatched, gently slide the free end of the camera ribbon cable into the slot between the latch and the rest of the bracket such that the blue backing on the ribbon cable is facing the Ethernet port at the rear of the robot. Once inserted, gently close the latch.

- Take the RasPi Robot V3 board and line up the socket on the bottom such that the front of the board (where all the green screw terminals are) is lined up with the front most pins on the Raspberry Pi computer’s GPIO pins. Be sure both rows are lined up and then gently press down to attach the board to the Raspberry Pi computer.

- Tuck the Camera ribbon cable under the free side of the RasPi Robot board.

- Unscrew the 6 green terminal screws on the RasPi Robot board on the side closest to the HDMI port.

- Following the labels on the board, insert the 2 wires for the left motor into the 2 screw terminals labeled L and tighten each terminal. Repeat for the Right motors into the R terminals.

NOTE: if you operate your robot and the motors seem to spin the wrong way, you need to swap the motor wires on that motor to the screw terminals they are in. - Take the battery connector wire and insert the red wire into the +V terminal and the black wire into the GND terminal. Tighten the screws.

- Insert USB Wifi adaptor (if using a Raspberry Pi 2 computer. If using a Raspberry Pi 3 computer you can skip this step as the model 3 has Wifi built in.)

- Finally, slide the battery pack in under the Raspberry Pi computer, between the standoffs (we used Velcro® to help hold them in place), and connect the battery pack to the battery terminal.

- Follow the instructions

Software Instructions

Link to our software instruction at https://github.com/joemirizio/mars-explorer.

Note: if you find that the robot is moving too fast or too slow, increase/decrease the motor_voltage (line 11 in src/main/python/config.ini)

Additional Information:

We're engineering a better tomorrow.

Your individual skills play a critical role in changing the way the world works and helping us develop products that make it a safer place to achieve your goals. Our teams are made up of diverse employees from a wide range of disciplines and backgrounds, working together to tackle complex challenges and push the boundaries of innovation.

Explore our skill areas to find the right opportunity for you.