Protection for the deep space journey

If you think landing a spacecraft on another planet is hard, have you ever wondered how that precious cargo is protected through the universe’s harshest environments in space?

The answer is the aeroshell.

At Lockheed Martin, we’ve built aeroshells for a variety of missions beginning in the 1970s. From all 10 of NASA’s Mars-bound landers and rovers, to Earth sample return missions from asteroids and comets, to the human-carrying Orion spacecraft — we’ve been building aeroshells for over 40 years to ensure we protect what matters most.

Read on for more about the importance of thermal protection systems and how aeroshells are made.

Why do spacecraft need a thermal protection system anyway?

The thermal protection system (TPS) on a spacecraft protects it from the intense heat that automatically occurs during a spacecraft’s atmospheric reentry — sometimes resulting in temperatures upward of 5000°F.

The TPS’ most notable feature is the aeroshell.

How do aeroshells work?

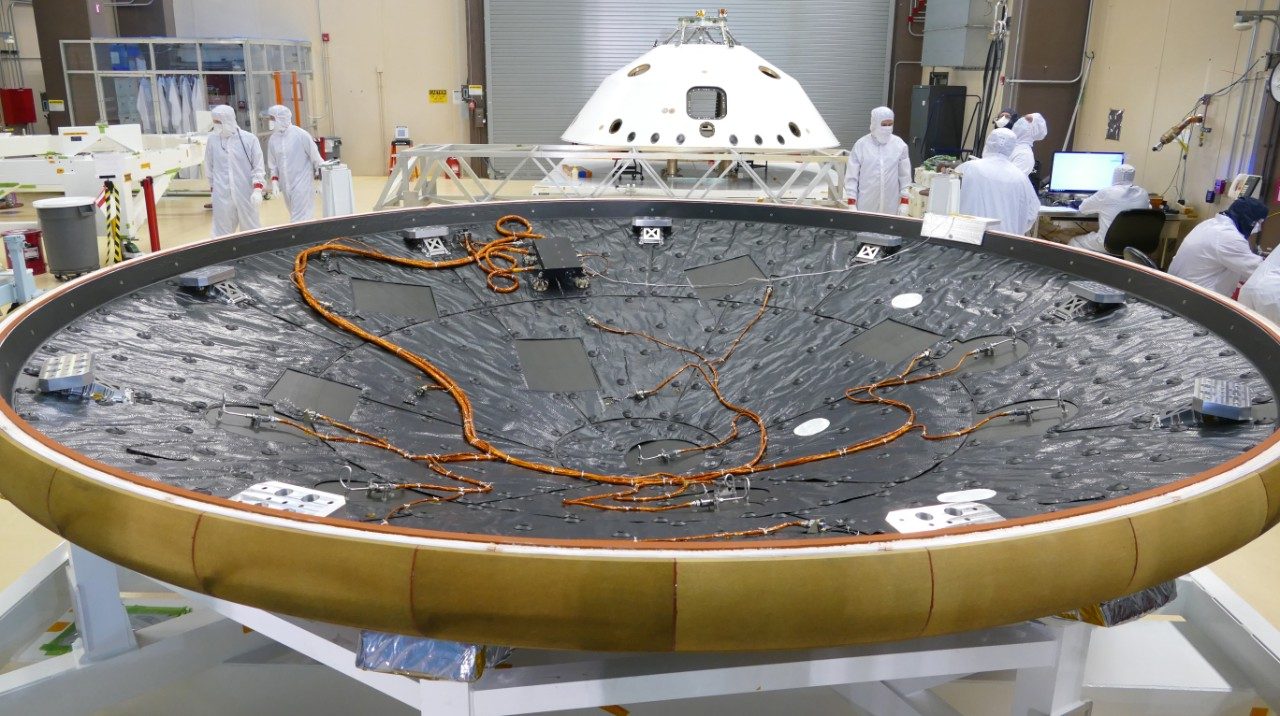

An aeroshell is made up of two parts: a heat shield and a backshell. Together, they encapsulate the spacecraft, tucking its science instruments, descent stage and other operational equipment safely inside.

The aeroshell’s shining moment occurs during entry, decent and landing (EDL). As the spacecraft performs a variety of maneuvers to safely land at its destination, the heat shield quite literally shields the spacecraft from the extreme heat generated during the initial descent through a planet’s atmosphere (typically around 2,700°F on Mars). In addition, the heat shield’s natural aerodynamics serve as a “brake” to help slow the spacecraft.

The cone-shaped backshell structure also plays an important role during EDL. The backshell supports the parachute and other mechanisms needed for a safe landing, including electronics and batteries. Plus, the backshell has holes for the small thrusters that help keep the spacecraft correctly oriented.

Engineering the aeroshell for Mars 2020

NASA’s Mars 2020 mission touched down in the treacherous Jezero Crater area — a region filled with boulders, rocky cliffs and shifting sand dunes — on Feb. 18, 2021.

The Perseverance rover will search for signs of ancient life and collect samples for possible return to Earth. Its activities include the first-ever flight of an aircraft on another planet, made by the Ingenuity drone helicopter — which will be released via a special delivery system built by Lockheed Martin. The findings of this mission could hold the key to how we understand Mars' past and Earth's future.

At 14.9 feet in diameter, this Lockheed Martin-built aeroshell is one of the two largest ever made for a planetary mission — equal in size to its predecessor, the Mars Science Laboratory aeroshell. Mars 2020’s heat shield — the part of an aeroshell that bears the brunt of the heat — is coated in an especially durable, ablative material called PICA. Its backshell uses an aluminum honeycomb structure sandwiched between graphite-epoxy face sheets and hand-packed with SLA-561V — a low conductivity ablative material whose texture has been compared to kinetic sand.

The Mars 2020 mission — carrying the Perseverance rover and Ingenuity helicopter drone — entered the thin Martian atmosphere at around 12,500 mph and 2,370°F before its parachutes and aerodynamics significantly slowed the descent.

There are also some cool pieces of tech integrated into Mars 2020’s aeroshell:

- The spacecraft’s descent stage includes a sky crane that lowered the rover to the surface of Mars for a soft landing at just under 2 mph.

- Mars 2020’s closest relative, Mars Science Laboratory, was outfitted with special instrumentation called MEDLI to characterize the aerodynamic environment. For Mars 2020, NASA engineers developed a new iteration of this tech called MEDLI2, which observed a broader range of entry conditions and provided NASA’s first-ever measurement of the heat experienced by an entry vehicle’s backshell. This will help scientists better understand the entry environment, and it will also help us engineer future spacecraft to even better protect cargo — and eventually, humans.

Three questions with an aeroshell engineer

David Scholz was Lockheed Martin’s principal engineer for the Mars 2020 aeroshell and has loads of experiencing crafting aeroshells for NASA’s planetary missions over the years. We asked him about what it’s like designing the critical system protecting the spacecraft.

When did you begin working for Lockheed Martin and what’s your day-to-day job look like?

Scholz: I spent about 10 years at other places before coming to Lockheed Martin in 1996. I started working in our composite development shop before moving over to work on the deep space exploration programs. Now I’m what they call a technical lead, which means I help plan out the programs as far as how we’re going to get the hardware designed, built, tested and delivered.

What’s your role on the Mars 2020 mission?

Scholz: I was the principal engineer for the aeroshell, so I was responsible for getting the aeroshell designed, built, tested and delivered. The aeroshell was the biggest piece of hardware we delivered for that particular mission, but we also built some other pretty impressive tech for it, including wiring harnesses and the helicopter deployment system.

I saw some photos of the Mars 2020 backshell fill event. Can you describe what that was and why it’s important?

Scholz: The material you saw being installed on the backshell is an ablator material that protects the aeroshell when it hits the atmosphere and gets extremely hot. The particular material used on Mars 2020 is called SLA-561V, with the S-L-A standing for “super light ablator.” It was developed for Viking all the way back in the 1970s and has been used on numerous heatshields and backshells since then.

For the full interview, including some tidbits about how the Orion aeroshell compares with the Mars 2020 aeroshell, subscribe to our email newsletter:

We're engineering a better tomorrow.

Your individual skills play a critical role in changing the way the world works and helping us develop products that make it a safer place to achieve your goals. Our teams are made up of diverse employees from a wide range of disciplines and backgrounds, working together to tackle complex challenges and push the boundaries of innovation.

Explore our skill areas to find the right opportunity for you.